MXIHY WB 01 High End Aluminum Cap With Silicone Handle Portable Life Hammer

In our daily life, sometime we will meet some emergency situation, like driving in rainstorm weather. The

Digital manufacturing for plastic prototypes and on-demand production parts. Request an injection molding quote today.

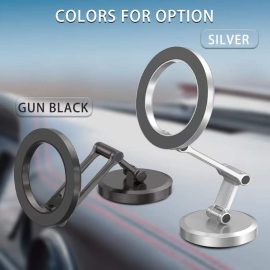

| Type: | Car Phone Holder |

|---|---|

| Model Number: | MC-27 |

| Material: | ZINC+ Magnets + Mylar piece + PC + Steel set screws |

| Type: | Car phone holder |

|---|---|

| Model Number: | MC-24 |

| Material: | Zinc + ABS + Steel + Magnets + Mylar piece |

| Type: | Car phone holder |

|---|---|

| Model Number: | MC-23 |

| Material: | Zinc Alloy+ Arcylic+ Magnets + TPU + ABS |

We combine scientific (or decoupled) molding techniques, which optimize and lock in processing parameters to ensure part consistency—with extra attention paid to critical-to-quality dimensions using our proprietary automated CMM process. Plus, with every order you’ll get:

Because of the initial capital investment in tooling, injection molding makes sense for higher volumes of parts. Our mold cost starts at $1,495 and will vary depending on part geometry and complexity. Other factors that will impact injection molding cost are lead times and material.

The largest size we can support with plastic injection molding is 18.9 in. x 29.6 in. x 8 in. (480mm x 751mm x 203mm).

Unmatched Lead Times

Reduce your product development cycle by weeks—sometimes months—and bridge to production with injection-molded parts within days. Some injection molding orders can ship in as fast as 1 day.

Design for Manufacturing Feedback

Every quote includes real-time pricing and design analysis. We evaluate your 3D CAD and help identify any features that may pose challenges during the molding process such as difficult to machine undercuts and insufficient draft.

No Minimum Order Quantities (MOQs)

Procuring parts on demand, without MOQs, helps you manage market or demand volatility and provides a cost-effective source for bridge production, line-down emergencies, end-of-life production, or product customization.

Injection Molding Expertise

We’ll work with you throughout the course of your project to help you quickly move from prototyping to production, including finishing options and inspection reporting.

In our daily life, sometime we will meet some emergency situation, like driving in rainstorm weather. The

This is introduction for MXIHY laptop stand, it can be adjusted in six levels height. And we can

MXIHY MP-19 Double Folding Arm Ring Phone Holder was popular in the world, it can be used

About our bicycle mobile phone holder, we should amount the clamp on your bike or motorcycle handles at

In our daily life, we would like to use our phones in hand on walking or you want

© 2022 Shenzhen Xinruida Electronic Hardware Plastic Co., Ltd